Nowadays, when more and more attention is focused on environmental protection and energy savings, when planning the construction of a new house, we must not forget about one of the key aspects - ventilation. Traditional methods are increasingly giving way to innovative solutions, including mechanical ventilation with heat recovery, which may prove to be a cost-saving step on the way to sustainable and efficient use of energy.

Is such an option expensive and unattainable for the average house builder? While the initial investment in mechanical ventilation with heat recovery may seem expensive, the long-term benefits far outweigh the initial outlay.

When we look at traditional gravity ventilation, although it seems at first glance to be a cheaper solution, we must remember about hidden costs and inefficiencies. Ventilation chimneys, material and maintenance costs, and heat loss resulting from heating the cold air supplied to the building are elements that in the long run may exceed the costs of mechanical ventilation.

Just look at the picture below and you can immediately see that losses due to air exchange are a significant cost in heating a building, even after it has been insulated.

Today's homes are getting better insulated and airtight, necessitating more controlled ventilation. Traditional gravitational ventilation often fails to cope with this challenge, leading to problems with the air quality inside the building, especially after thermal modernization.

There is also an option of mechanical ventilation for existing buildings that do not have the possibility of installing a central ventilation system. It is a decentralized system

To sum up, both in a new and old house, ventilation is an important aspect that is worth considering from the perspective of energy savings and living comfort. Innovative solutions, such as mechanical ventilation with heat recovery, offer not only more efficient use of energy, but also better control over indoor air quality. With the long-term financial and environmental benefits in mind, it's worth considering these advanced technologies when planning your new home.

Carefully selected recuperator and installation, as well as proper connection and appropriate design, will enable long-term use of high quality air in your home and save on heating bills.

How does recuperation work?

Mechanical ventilation is an air exchange system using a mechanical drive. Unlike natural ventilation, also known as gravitational ventilation, the mechanical system is not dependent on external conditions, and the intensity of its operation can be individually adjusted to your needs.

Our apartment is a space where a certain number of people are always present. It often happens that the rooms get stuffy and the air seems stale. This is proof that natural air exchange is not adjusted to real needs and often requires manual ventilation, which can result in unhealthy draughts. In the case of mechanical ventilation, we can not only regulate the intensity of air exchange, but also avoid unnecessary cooling of rooms, even during events in a larger group. What's more, we recover heat from the exhausted air, which has a positive effect on our household budget.

The mechanical ventilation system consists of several elements that allow fresh air to be taken from the outside, moved through all the rooms in the building and released to the outside. The heart of the whole system is the central unit, known as the recuperator, which manages the process and recovers heat from the air in an intelligent way, without mixing it with the exhaust air.

The first element is plenum boxes, which are used to connect flexible ventilation ducts with diffusers. You can choose models made of stainless steel or fiber-reinforced polycarbonate. They allow the system to be installed both under the ceiling and directly on the ceiling. They are available in various connection variants and all have sleeves for connecting ventilation ducts with a built-in gasket and snap-on assembly. This guarantees quick and simple installation of plenum boxes in the installation.

The receivers of the supplied air are supply diffusers, and their proper arrangement is crucial for optimal air exchange throughout the building. We have to decide whether the air will be supplied from the floor, wall or ceiling, because there are three options. For best results, place the supply and exhaust points high, which is usually recommended.

Exhaust diffusers are placed in the so-called "dirty" rooms, such as the kitchen and bathroom, while supply diffusers are placed in other rooms. Equalization of the supply and exhaust air streams is ensured by elements of the exhaust system in places such as communication rooms, e.g. hall and staircase.

Diffusers should not be installed directly above the place where people stay, e.g. above a bed, desk or sofa. It is best to place them in places away from doors and exhaust openings, so that the entire volume of air in a given room participates in air exchange.

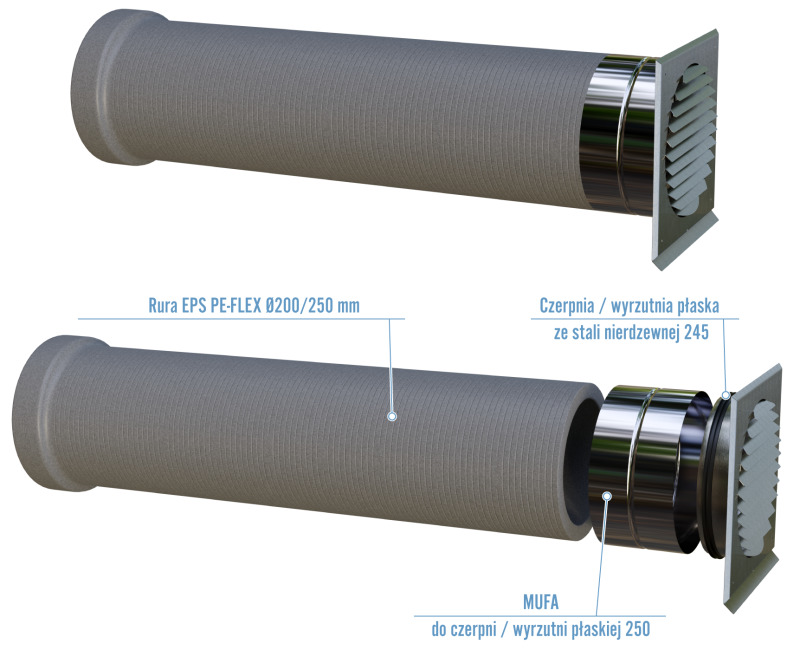

Ventilation ducts are the basic element responsible for the movement of air in the building. The PE-HD material ensures a smooth interior of the double-layer pipes, which are additionally protected against bacteria, fungi and static charging.

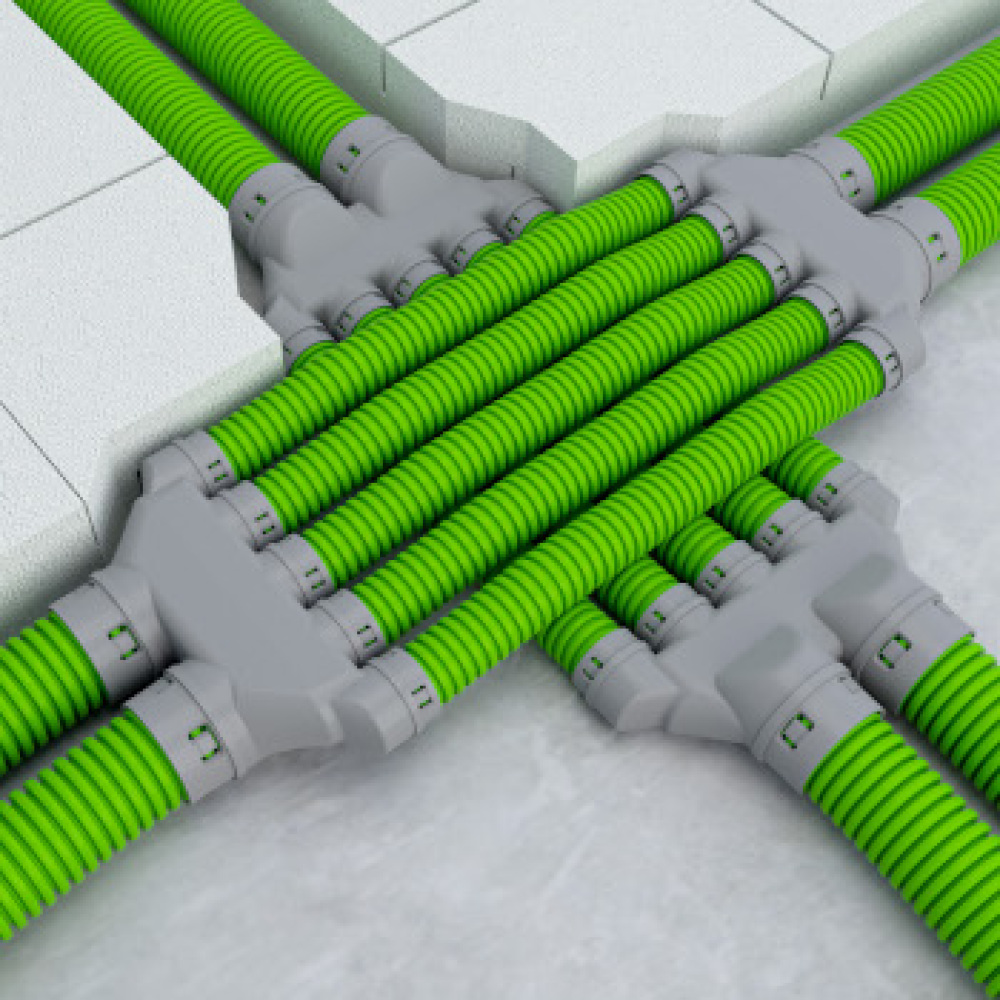

Ventilation adapters allow crossing different installations on one surface. It is important that ventilation ducts laid on the floor do not collide with underfloor heating ducts.

Distribution boxes are the starting point of the entire system and distribute the installation throughout the building. They are made of stainless steel and equipped with plastic couplings with snap-on assembly, adapted to the individual needs of each installation. All ventilation systems must include at least two manifolds - supply and exhaust.

The recuperator is a key element of the installation, responsible for air exchange and heat recovery. This device ensures thermal comfort, and the filters placed in it improve the air quality in the building. It consists of two fans - supply and exhaust - and a heat exchanger that separates the air streams, enabling heat recovery. Ventilation units with heat recovery - recuperators - can be equipped with a counter-current, cross-flow or rotary heat exchanger.

The central unit can be installed in the attic, attic, on the residential level in utility rooms or in the basement. The choice of location must take into account the ambient temperature, which should not fall below 5°C (otherwise the installation must be properly insulated). Providing access to the device, including filter replacement and maintenance, is also important. To avoid the penetration of noise into living quarters, the recuperator should not be installed close to the attic hatch, door, etc. It should be possible to drain the condensate to the sewage system, and the air supply and discharge ducts to the device should be as short as possible.

Air inlets and outlets are external elements of the installation, which should be protected against wind and rain. The location should allow access to clean air and benefit from cooler air in the summer. The lower edge of the air inlet should be at least 2 meters above ground level, but it is recommended to place it as high as possible, which can be achieved by installing it in a soffit. Avoid locating inlets near sources of smoke, fumes, and odors, and away from drains.

Do you have questions about this? Contact us , maybe we can help you.

The following video will briefly explain how recuperation works